A machinery room surveillance system consists of several key components that work together to monitor and protect the equipment in the room. These components include cameras, sensors, alarms, and a central monitoring system. The cameras provide visual surveillance of the machinery room, allowing operators to remotely monitor the equipment and detect any potential issues. The sensors are used to measure various parameters such as temperature, humidity, vibration, and gas levels, providing real-time data on the operating conditions. The alarms are triggered when abnormal conditions are detected, alerting operators to take immediate action. The central monitoring system collects and analyzes the data from the cameras and sensors, providing a comprehensive overview of the machinery room's status.

A machinery room surveillance system plays a crucial role in preventing equipment failures by providing early detection of potential issues. By continuously monitoring the operating conditions, the system can detect any abnormalities or deviations from the normal parameters. For example, if the temperature in the machinery room exceeds a certain threshold, the system can trigger an alarm, indicating a potential overheating problem. This allows operators to take immediate action, such as shutting down the equipment or adjusting the cooling system, before any serious damage occurs. By detecting and addressing issues early on, the system helps to prevent equipment failures and minimize downtime.

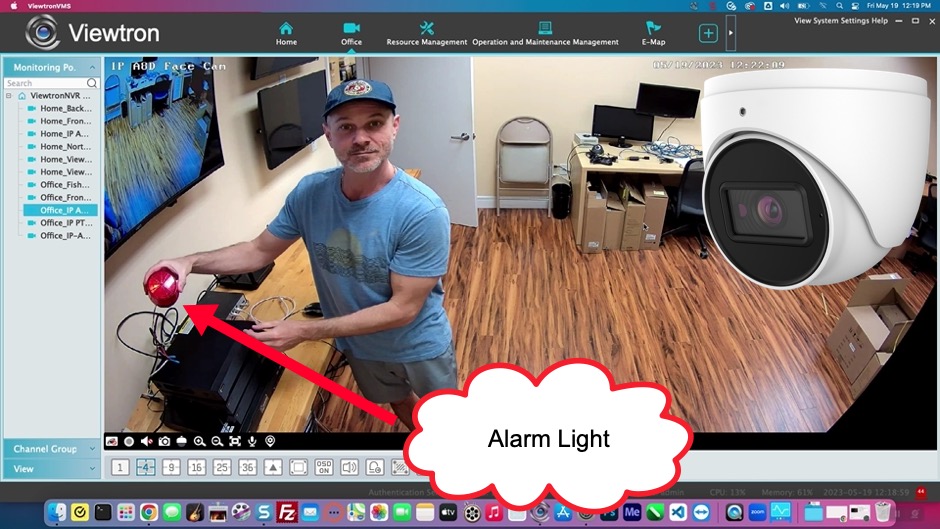

Remotely Trigger an Alarm Light Connected to a DVR Alarm Output using Windows / Mac Software. The post Remotely Trigger an Alarm Light via DVR Alarm Output first appeared on Security Camera & Video Surveillance Blog.

Posted by on 2023-05-22

Watch this video to learn how to determine in you can upgrade your old system. The post How-to Upgrade an Older Security Camera System to 4K first appeared on Security Camera & Video Surveillance Blog.

Posted by on 2023-05-16

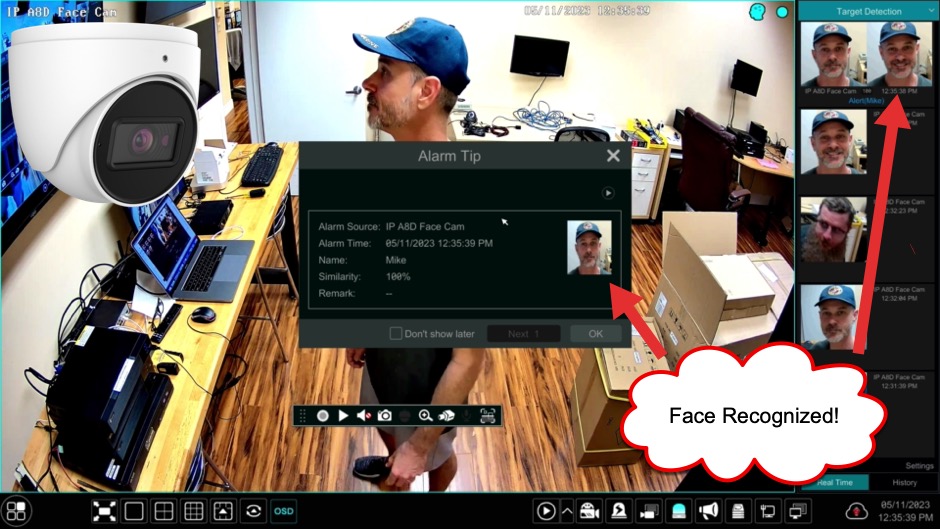

Setup a face detection alarm using a Viewtron facial recognition camera. The post Facial Recognition Camera Face Detection Alarm Setup first appeared on Security Camera & Video Surveillance Blog.

Posted by on 2023-05-12

How-to export the license plate database to a CSV file on Viewtron LPR camera systems. The post License Plate Database Export for Viewtron LPR Camera System first appeared on Security Camera & Video Surveillance Blog.

Posted by on 2023-05-08

Night time license plate recognition testing using a Viewtron LPR camera and NVR. The post LPR Camera Night Time License Plate Recongition first appeared on Security Camera & Video Surveillance Blog.

Posted by on 2023-04-17

There are several common types of sensors used in machinery room surveillance systems. Temperature sensors are used to monitor the temperature levels in the room and detect any overheating issues. Humidity sensors measure the moisture levels, ensuring that the room is maintained within the optimal range. Vibration sensors detect any abnormal vibrations or movements in the equipment, indicating potential mechanical problems. Gas sensors are used to monitor the presence of harmful gases, such as carbon monoxide or refrigerant leaks, ensuring a safe working environment. These sensors provide real-time data that is crucial for detecting abnormal operating conditions and preventing equipment failures.

CCTV Security Camera Placement Strategies for Commercial Properties

A machinery room surveillance system detects abnormal operating conditions through the use of sensors and data analysis. The sensors continuously monitor various parameters, such as temperature, humidity, vibration, and gas levels. The data collected by these sensors is then analyzed by the central monitoring system, which compares it to predefined thresholds or patterns. If any parameter exceeds the set limits or deviates from the expected patterns, the system triggers an alarm, indicating an abnormal operating condition. For example, if the temperature suddenly spikes or the vibration levels exceed the normal range, the system will detect these abnormalities and alert the operators to investigate and take appropriate action.

Integrating a machinery room surveillance system with a building management system offers several benefits. Firstly, it allows for centralized monitoring and control of both the machinery room and the overall building systems. This integration enables operators to have a comprehensive view of the entire facility, making it easier to identify any potential issues or correlations between different systems. Secondly, it enables automated responses and actions based on the data collected by the machinery room surveillance system. For example, if an abnormal operating condition is detected in the machinery room, the building management system can automatically adjust the HVAC system or notify maintenance personnel. This integration enhances the efficiency and effectiveness of the overall building management and maintenance processes.

A machinery room surveillance system can help improve energy efficiency in several ways. Firstly, by continuously monitoring the operating conditions, the system can detect any energy wastage or inefficiencies. For example, if the temperature in the machinery room is too low or the cooling system is running unnecessarily, the system can alert operators to adjust the settings and optimize energy usage. Secondly, the system can provide valuable data and insights for energy management and optimization. By analyzing the data collected from the sensors, operators can identify trends, patterns, and potential areas for improvement. This information can be used to implement energy-saving measures, such as adjusting equipment schedules or optimizing the use of resources.

To maintain and troubleshoot a machinery room surveillance system, several best practices should be followed. Regular maintenance and calibration of the sensors and cameras are essential to ensure accurate and reliable data. Operators should also regularly check the system's alarms and notifications to ensure they are functioning properly. It is important to have a clear understanding of the normal operating conditions and thresholds for each parameter, so that any deviations can be quickly identified and addressed. Additionally, operators should regularly review and analyze the data collected by the system to identify any trends or patterns that may indicate potential issues. Finally, proper documentation and record-keeping of maintenance activities, troubleshooting steps, and system performance are crucial for future reference and analysis.

To effectively monitor production lines using CCTV, it is crucial to implement a comprehensive surveillance system that incorporates advanced features and technologies. Firstly, installing high-resolution cameras strategically positioned along the production line allows for detailed monitoring of the entire process. These cameras should be equipped with pan-tilt-zoom capabilities to provide a wide coverage area and the ability to zoom in on specific areas of interest. Additionally, integrating video analytics software into the CCTV system enables real-time monitoring and analysis of production line activities. This software can detect anomalies, such as equipment malfunctions or deviations from standard operating procedures, and send alerts to the appropriate personnel. Furthermore, implementing a centralized monitoring station equipped with multiple screens and video management software allows operators to view and manage multiple camera feeds simultaneously. This enhances situational awareness and facilitates prompt response to any issues that may arise. Regular maintenance and calibration of the CCTV system are also essential to ensure optimal performance and accurate monitoring of the production lines. By employing these advanced technologies and practices, companies can effectively monitor their production lines using CCTV, ensuring smooth operations and timely detection of any potential problems.

Monitoring loading bays can be effectively done by implementing a comprehensive system that incorporates various technological tools and processes. One crucial aspect is the installation of surveillance cameras strategically positioned to cover all areas of the loading bay. These cameras should be equipped with advanced features such as high-resolution imaging, night vision capabilities, and motion detection. Additionally, integrating sensors and alarms can provide real-time notifications for any unauthorized access or suspicious activities. Implementing an automated inventory management system can also aid in monitoring loading bays by tracking the movement of goods and ensuring accurate documentation. Regular audits and inspections should be conducted to identify any potential safety hazards or compliance issues. By employing these measures, businesses can effectively monitor loading bays and enhance overall security and efficiency.

Monitoring indoor plants using CCTV can be achieved by setting up a comprehensive surveillance system that includes strategically placed cameras, motion sensors, and a centralized monitoring station. The cameras should be positioned in a way that covers all areas where the plants are located, ensuring maximum visibility. Additionally, motion sensors can be installed to detect any movement or activity around the plants, triggering the cameras to start recording. The footage captured by the CCTV cameras can then be streamed or stored in a secure location, allowing for real-time monitoring or later review. By implementing this surveillance system, individuals can closely observe the health and growth of their indoor plants, detect any potential issues such as pests or diseases, and take appropriate actions promptly.

Surveillance in retail displays should cover areas such as product placement, customer behavior, theft prevention, and overall display effectiveness. This includes monitoring the arrangement and organization of products on shelves or racks, observing how customers interact with the displays and products, implementing security measures to prevent shoplifting or theft, and analyzing the impact of the displays on sales and customer engagement. Additionally, surveillance should also encompass monitoring for any potential safety hazards or compliance with store policies and regulations. By covering these various aspects, retailers can ensure the overall security and success of their retail displays.