Production line monitoring is the process of tracking and analyzing the performance of manufacturing processes in real-time. It involves collecting data from various sensors and machines on the production line and using that data to identify potential issues and areas for improvement. Production line monitoring is important in manufacturing because it helps companies optimize their production processes, reduce waste, and improve product quality. By monitoring production lines, companies can identify bottlenecks, reduce downtime, and increase overall efficiency.

Real-time monitoring of production lines is essential for identifying bottlenecks and improving efficiency. By collecting data from sensors and machines in real-time, companies can quickly identify issues and take corrective action before they become major problems. For example, if a machine on the production line is running slower than expected, real-time monitoring can alert operators to the issue and allow them to adjust the machine's settings to improve performance. Real-time monitoring also helps companies identify trends and patterns in production data, which can be used to optimize processes and improve overall efficiency.

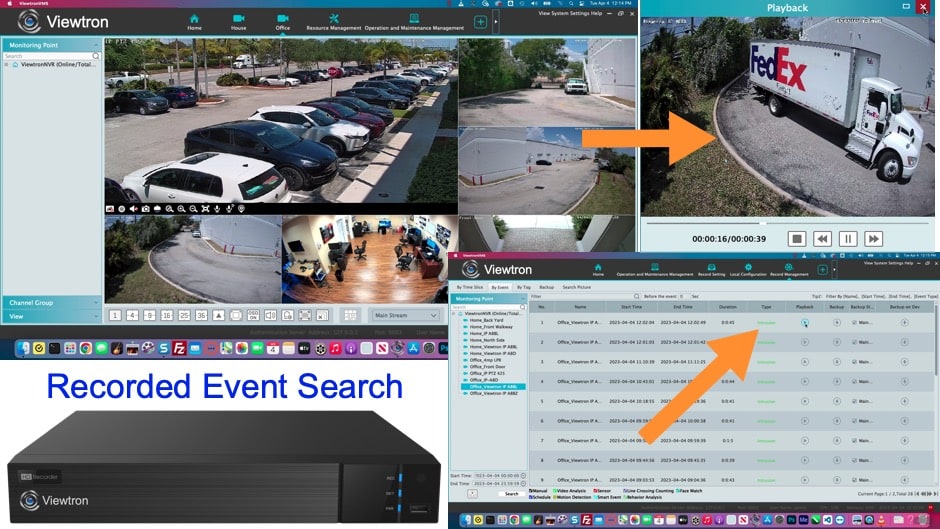

Search & Playback AI and Motion Detection Events w/ Viewtron CMS DVR Software. The post CMS DVR Software Search, Playback & Backup AI Motion Events first appeared on Security Camera & Video Surveillance Blog.

Posted by on 2023-04-05

Check out the spot monitor for IP cameras function of our 32ch NVR. The post Spot Monitor for IP Cameras on 32 Channel NVR first appeared on Security Camera & Video Surveillance Blog.

Posted by on 2023-03-28

Video demo controlling the motorized zoom lens of a 4K CCTV camera from a Viewtron DVR. The post 4K CCTV Camera with Motorized Zoom Lens first appeared on Security Camera & Video Surveillance Blog.

Posted by on 2023-03-23

View security cameras that are connected to multiple DVR locations with the Viewtron mobile app. The post View Multiple Security Camera DVR Locations via Mobile App first appeared on Security Camera & Video Surveillance Blog.

Posted by on 2023-03-14

The key metrics and indicators that are monitored in production line monitoring include cycle time, throughput, yield, and quality. Cycle time refers to the time it takes to complete a single production cycle, while throughput refers to the number of units produced per unit of time. Yield refers to the percentage of units produced that meet quality standards, while quality refers to the overall level of product quality. Other metrics that may be monitored include machine uptime, downtime, and maintenance requirements.

CCTV Security Camera Placement Strategies for Commercial Properties

Production line monitoring systems can help detect and prevent quality issues by monitoring key metrics and indicators in real-time. For example, if the yield of a particular production line drops below a certain threshold, the monitoring system can alert operators to the issue and allow them to take corrective action. Similarly, if a machine on the production line is producing defective parts, the monitoring system can detect the issue and alert operators to the problem. By detecting and preventing quality issues early, companies can reduce waste, improve product quality, and increase customer satisfaction.

The benefits of implementing automated production line monitoring systems include increased efficiency, reduced downtime, and improved product quality. Automated monitoring systems can collect and analyze data in real-time, allowing companies to quickly identify issues and take corrective action. They can also help companies optimize their production processes by identifying areas for improvement and providing real-time feedback to operators. Additionally, automated monitoring systems can reduce the need for manual data collection and analysis, freeing up operators to focus on other tasks.

Production line monitoring systems can help reduce downtime and maximize productivity by identifying potential issues before they become major problems. By monitoring key metrics and indicators in real-time, companies can quickly identify issues such as machine breakdowns or material shortages and take corrective action. This can help reduce downtime and keep production lines running smoothly. Additionally, by analyzing production data, companies can identify areas for improvement and optimize their production processes to maximize productivity.

Some common challenges faced in implementing and maintaining production line monitoring systems include data integration, system complexity, and operator training. Integrating data from multiple sources can be challenging, especially if the data is stored in different formats or systems. Additionally, production line monitoring systems can be complex and require specialized knowledge to operate and maintain. Finally, operators may require training to use the system effectively and interpret the data collected. To overcome these challenges, companies may need to invest in specialized software and hardware, as well as provide ongoing training and support to operators.

To ensure comprehensive surveillance in construction materials storage areas, it is crucial to implement a robust and multifaceted security system. This can include the installation of high-definition surveillance cameras strategically positioned to cover all angles and blind spots. Additionally, employing motion sensors, access control systems, and alarm systems can further enhance the security measures. Regular monitoring and recording of the surveillance footage should be conducted to promptly identify any suspicious activities or potential threats. Furthermore, implementing advanced technologies such as facial recognition software, biometric access control, and remote monitoring capabilities can provide an added layer of security. Regular inspections and maintenance of the security equipment should also be carried out to ensure optimal functionality. By adopting these comprehensive surveillance measures, construction materials storage areas can be effectively safeguarded against unauthorized access, theft, and vandalism.

To monitor outdoor smoking areas using CCTV, one can install high-resolution cameras strategically positioned to cover the entire area. These cameras can be equipped with infrared technology to ensure visibility in low light conditions. Additionally, motion detection and facial recognition software can be integrated to accurately identify individuals engaging in smoking activities. The footage can be streamed live to a central monitoring station or stored for later review. Furthermore, the use of weatherproof and vandal-resistant cameras is essential to ensure continuous surveillance in outdoor environments. By implementing these measures, organizations can effectively monitor outdoor smoking areas and enforce smoking policies.

Optimizing camera placement for monitoring cash register areas requires careful consideration of various factors. Firstly, it is crucial to position the cameras in a way that provides a clear and unobstructed view of the cash register and surrounding areas. This may involve placing the cameras at strategic angles to capture different perspectives and minimize blind spots. Additionally, it is important to ensure that the cameras are positioned at an optimal height to capture facial features and other identifying details of individuals interacting with the cash register. Furthermore, the use of wide-angle lenses can help maximize the coverage area and minimize the number of cameras required. Considering the lighting conditions is also essential, as proper lighting can enhance the quality of the footage. Lastly, it is advisable to consult with security professionals or experts in surveillance systems to determine the most effective camera placement for monitoring cash register areas.

To effectively monitor delivery entrances, it is important to implement a comprehensive security system that includes surveillance cameras, access control systems, and security personnel. The surveillance cameras should be strategically placed to cover all angles of the delivery entrance and should be equipped with motion sensors and night vision capabilities. The access control system should require all delivery personnel to provide identification and be authorized before entering the premises. Security personnel should be trained to monitor the cameras and access control system, as well as to conduct regular patrols of the delivery entrance area. Additionally, it may be beneficial to implement a system for tracking deliveries and ensuring that all deliveries are properly logged and accounted for. By implementing these measures, businesses can effectively monitor delivery entrances and reduce the risk of theft, vandalism, and other security breaches.

When it comes to ensuring the safety and security of classrooms, there are several measures that should be taken. First and foremost, it is crucial to have a robust access control system in place. This can include measures such as installing secure entryways with key card or biometric access, as well as implementing visitor management systems to monitor and track individuals entering the classroom. Additionally, the installation of surveillance cameras can provide an extra layer of security, allowing for real-time monitoring and recording of any suspicious activities. It is also important to have a clear emergency response plan in place, which includes regular drills and training sessions for both students and staff. This plan should cover various scenarios, such as lockdown procedures, evacuation routes, and communication protocols. Furthermore, the implementation of a comprehensive communication system, such as a two-way radio network, can facilitate quick and effective communication during emergencies. Lastly, it is essential to have a strong relationship with local law enforcement agencies, who can provide support and assistance in case of any security threats. By implementing these security measures, classrooms can create a safe and secure environment for students and staff alike.

Monitoring administrative offices using CCTV can be achieved by implementing a comprehensive surveillance system that incorporates various advanced technologies. Firstly, it is crucial to strategically place high-resolution cameras in key areas such as entrances, exits, hallways, and common spaces. These cameras should be equipped with features like motion detection, night vision, and pan-tilt-zoom capabilities to ensure optimal coverage and flexibility. Additionally, integrating the CCTV system with video analytics software can enhance monitoring capabilities by enabling functions like facial recognition, object tracking, and behavior analysis. This integration can also facilitate real-time alerts and notifications for any suspicious activities or unauthorized access. Furthermore, the CCTV system should be connected to a centralized monitoring station, where trained personnel can continuously monitor the live feeds and review recorded footage when necessary. Implementing secure storage solutions, such as network video recorders or cloud-based platforms, is essential to ensure the retention and accessibility of video data. Regular maintenance and updates of the CCTV system, including camera calibration and software upgrades, are also vital to ensure its optimal performance. By employing these comprehensive measures, the monitoring of administrative offices using CCTV can be highly effective in enhancing security and maintaining a safe environment.