The standard procedures for inspecting incoming shipments in the shipping and receiving area typically involve several steps to ensure the accuracy and quality of the received goods. Upon arrival, the shipment is first checked against the accompanying documentation, such as the packing slip or purchase order, to verify that the correct items and quantities have been delivered. The packaging is then visually inspected for any signs of damage or tampering. If any discrepancies or issues are identified, they are immediately reported to the appropriate personnel. Additionally, random sampling or thorough inspections may be conducted to ensure the quality and compliance of the received goods with relevant standards or regulations.

To ensure that all outgoing shipments are properly packaged and labeled, the shipping and receiving area follows specific procedures. Before packaging, the items are carefully inspected to ensure they are in the correct condition and meet the necessary requirements. The packaging materials used are selected based on the nature of the items being shipped, taking into consideration factors such as fragility, weight, and size. Once the items are securely packaged, proper labeling is applied, including the recipient's address, tracking number, and any other required information. This labeling process is done meticulously to avoid any confusion or misplacement during transit.

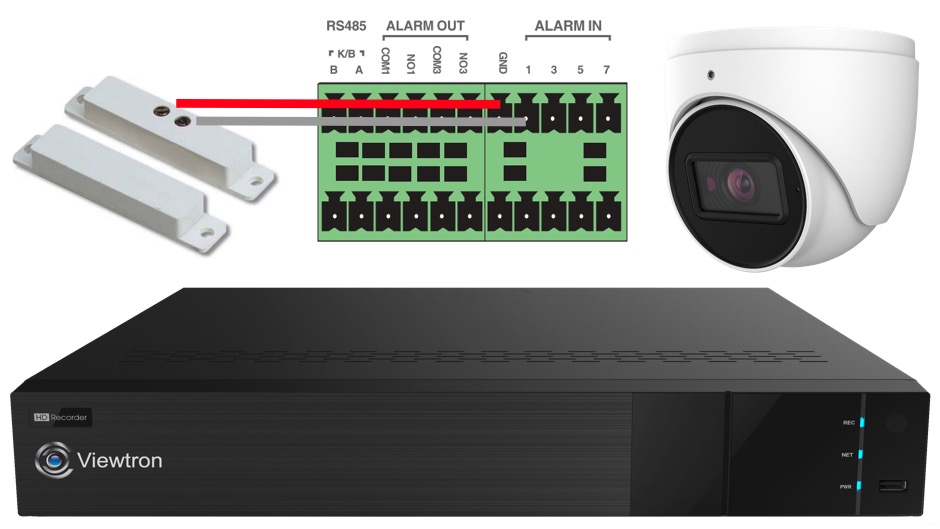

Watch this video to learn how to connect a magnetic door sensor to the alarm input of Viewtron security DVRs. The post Magnetic Door Sensor / Alarm Input Recording on Viewtron DVRs first appeared on Security Camera & Video Surveillance Blog.

Posted by on 2023-12-18

Viewtron 4mp LPR camera license plate detection software testing between 20 and 90 feet. The post 4mp LPR Camera License Plate Detection Software Testing first appeared on Security Camera & Video Surveillance Blog.

Posted by on 2023-12-08

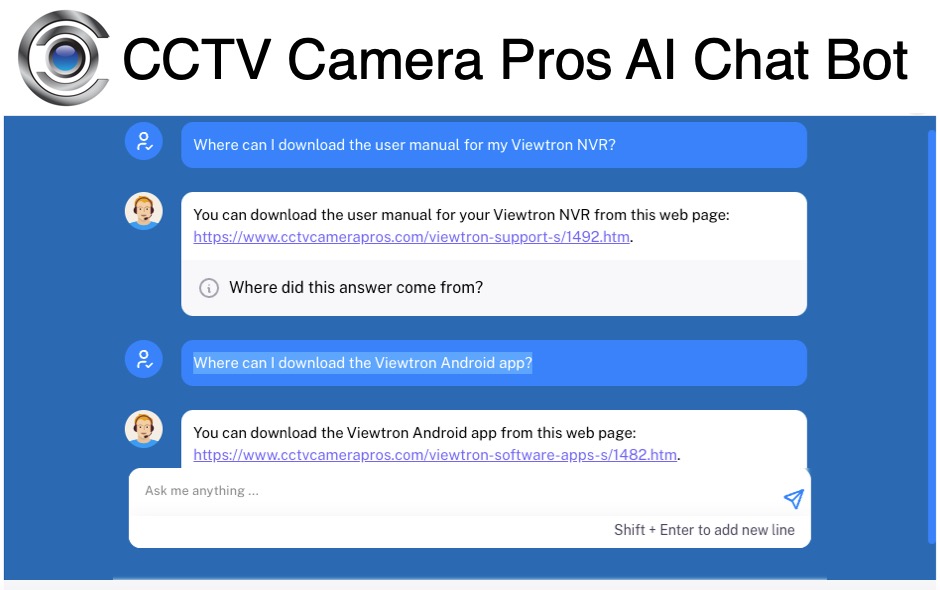

We recently launched an AI chat bot on CCTV Camera Pros website. The goal is to train our chat bot The post Please Ask CCTV Camera Pros AI Chat Bot a Question first appeared on Security Camera & Video Surveillance Blog.

Posted by on 2023-11-28

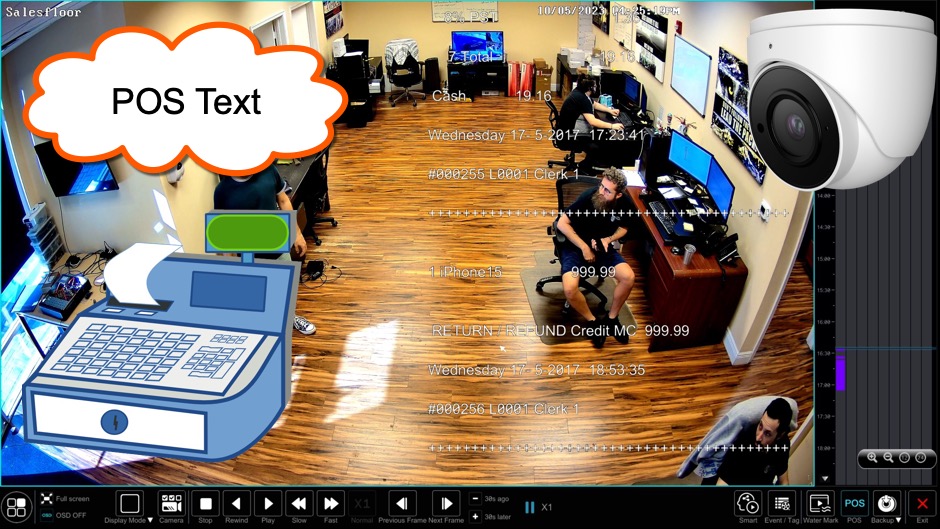

Viewtron security camera systems support POS text overlay for cash register cameras. The post POS Text Overlay for Cash Register Camera first appeared on Security Camera & Video Surveillance Blog.

Posted by on 2023-10-18

Various measures are in place to prevent theft or damage to packages in the shipping and receiving area. Access to the area is typically restricted to authorized personnel only, with security measures such as surveillance cameras, alarms, and secure entry systems in place. Additionally, inventory management systems are utilized to track the movement of packages and ensure accountability. Regular audits and checks are conducted to identify any discrepancies or potential security breaches. Staff members are trained to handle packages with care and follow proper handling procedures to minimize the risk of damage. In cases where high-value or sensitive items are involved, additional security measures, such as requiring signatures upon delivery, may be implemented.

The shipping and receiving area has established procedures for handling returns or damaged goods. When a return or damaged item is identified, it is first documented and reported to the appropriate personnel. Depending on the nature of the issue, the item may be inspected further to determine the cause of damage or defect. If the issue is due to a manufacturing defect or error, the item may be returned to the supplier for replacement or refund. In cases where the damage occurred during transit, the shipping carrier may be contacted to initiate a claim process. The necessary paperwork and documentation are completed to ensure proper record-keeping and resolution of the issue.

The process for tracking inventory in the shipping and receiving area typically involves the use of inventory management systems. Upon receipt of a shipment, the items are logged into the system, including relevant details such as item description, quantity, and supplier information. This allows for real-time tracking of inventory levels and facilitates accurate stock management. As items are prepared for shipment, they are scanned or manually recorded in the system to update the inventory records. Regular inventory counts and reconciliations are conducted to ensure the accuracy of the recorded data. This tracking process enables efficient inventory control, minimizes stockouts or overstock situations, and provides valuable insights for forecasting and planning purposes.

The shipping and receiving area has specific protocols in place to handle hazardous materials or items that require special handling. These protocols are designed to ensure compliance with relevant safety regulations and minimize the risk of accidents or incidents. Staff members responsible for handling hazardous materials receive specialized training to understand the proper handling procedures, including the use of personal protective equipment (PPE) and adherence to specific storage and transportation requirements. Hazardous materials are typically segregated from other items and stored in designated areas with appropriate safety measures, such as fire suppression systems or ventilation systems. Additionally, the shipping and receiving area maintains up-to-date knowledge of applicable regulations and ensures that all necessary permits or licenses are obtained for the handling and transportation of hazardous materials.

Employees working in the shipping and receiving area are required to undergo specific training to ensure compliance with safety regulations. This training covers various aspects, including proper handling and storage of goods, safe operation of equipment such as forklifts or pallet jacks, and emergency response procedures. Employees are educated on the potential hazards associated with their tasks and provided with the necessary knowledge and skills to mitigate risks. Training programs may include both theoretical instruction and practical demonstrations to ensure a comprehensive understanding of safety protocols. Regular refresher training sessions are conducted to reinforce knowledge and address any updates or changes in safety regulations. By investing in employee training, the shipping and receiving area aims to create a safe working environment and minimize the likelihood of accidents or injuries.

CCTV Security Camera Placement Strategies for Commercial Properties

To adequately cover a parking lot, the number of cameras required depends on various factors such as the size and layout of the parking lot, the level of security desired, and the specific needs of the location. Generally, a parking lot may require multiple cameras strategically placed to ensure comprehensive coverage. Factors to consider include the number of entrances and exits, blind spots, high traffic areas, and potential security risks. Additionally, the type of cameras used, such as fixed or pan-tilt-zoom (PTZ) cameras, can also impact the number needed. It is recommended to consult with a professional security expert who can assess the specific requirements of the parking lot and provide a tailored solution.

When it comes to ensuring the security of waiting rooms, there are several important measures that should be taken. Firstly, it is crucial to have a robust access control system in place, which may include the use of key cards or biometric authentication to restrict entry to authorized individuals only. Additionally, installing surveillance cameras strategically throughout the waiting area can help deter potential threats and provide valuable evidence in case of any incidents. It is also advisable to have trained security personnel present in the waiting room to monitor the area and respond promptly to any security concerns. Implementing proper lighting and visibility in the waiting room can further enhance security by reducing blind spots and creating a sense of safety. Furthermore, conducting regular risk assessments and implementing appropriate emergency protocols, such as evacuation plans and panic buttons, can help mitigate potential security risks. Lastly, ensuring that sensitive information is properly secured, such as by using privacy screens on computer monitors or providing secure storage for personal belongings, is essential to protect the privacy and confidentiality of individuals in the waiting room. By implementing these comprehensive security measures, waiting rooms can provide a safe and secure environment for all individuals.

To optimize surveillance in office cubicles, one can implement a combination of security cameras, motion sensors, and access control systems. By strategically placing high-resolution cameras in each cubicle, employers can monitor employee activity and ensure workplace safety. Motion sensors can be used to detect any unauthorized movement or activity in the cubicle area, while access control systems can restrict entry to only authorized personnel. Additionally, integrating these surveillance measures with advanced analytics software can provide real-time monitoring and alerts for any suspicious behavior. This comprehensive approach to surveillance can help maintain a secure and productive work environment in office cubicles.

To optimize surveillance in conference rooms, several measures can be taken. Firstly, installing high-resolution cameras with wide-angle lenses can provide comprehensive coverage of the entire room. Additionally, incorporating advanced video analytics technology can enhance the surveillance system by enabling features such as facial recognition, motion detection, and object tracking. Integrating the surveillance system with access control systems can further enhance security by allowing only authorized individuals to enter the conference room. Furthermore, implementing sound detection sensors can alert security personnel in case of any suspicious or unauthorized conversations. Regular maintenance and updates of the surveillance system are crucial to ensure its optimal performance. By implementing these measures, conference room surveillance can be optimized to ensure the safety and security of the premises.

When it comes to camera placements for back offices, there are several factors to consider in order to ensure optimal surveillance coverage. One important aspect is to strategically position the cameras in areas that provide a comprehensive view of the entire office space. This may include placing cameras at entrances and exits, near valuable assets or equipment, and in areas where sensitive information is stored. Additionally, it is crucial to consider the lighting conditions in the back office and adjust camera placements accordingly. This may involve installing cameras with low-light capabilities or positioning them in areas with adequate lighting. Furthermore, it is advisable to place cameras at different heights and angles to capture a variety of perspectives and minimize blind spots. By carefully considering these factors and utilizing the appropriate camera placements, back offices can enhance their security measures and ensure the safety of their assets and personnel.

To ensure comprehensive surveillance in warehouse aisles, it is crucial to implement a combination of advanced security measures and cutting-edge technology. Firstly, installing a network of high-resolution surveillance cameras strategically positioned throughout the aisles will provide a wide coverage area. These cameras should be equipped with features such as pan, tilt, and zoom capabilities to capture detailed footage of any suspicious activities. Additionally, integrating motion sensors and infrared technology into the surveillance system can enhance its effectiveness by detecting any movement or heat signatures in the aisles, even in low-light conditions. Furthermore, implementing a centralized monitoring system that utilizes artificial intelligence algorithms can enable real-time analysis of the video feeds, allowing for immediate identification of potential security threats. This system can also be integrated with access control systems, enabling the monitoring of individuals entering and exiting the aisles. Regular maintenance and testing of the surveillance equipment, along with training the warehouse staff on security protocols, will further ensure the comprehensive surveillance of warehouse aisles.