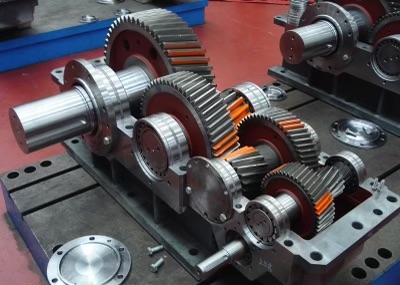

Gearbox Design Flaws and Failures

What are the common design flaws found in helical gearboxes?

Common design flaws in helical gearboxes often include issues such as misalignment of the gears, which can lead to increased noise, vibration, and wear. Another common flaw is inadequate lubrication, which can result in increased friction and heat generation, ultimately reducing the efficiency and lifespan of the gearbox. Additionally, poor material selection can lead to premature wear and failure of the gears, impacting the overall performance of the gearbox.