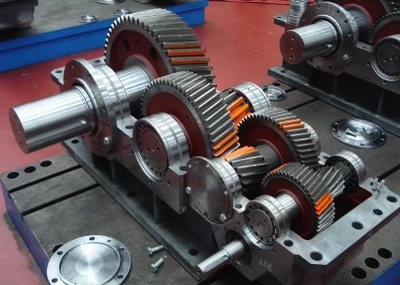

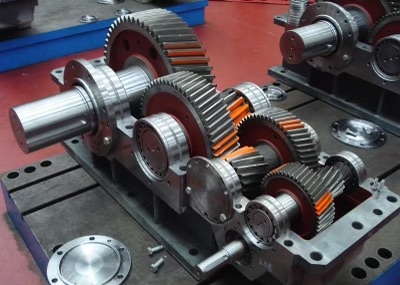

The integrity of the gearbox housing plays a crucial role in failure analysis as it serves as the primary protective barrier for the internal components of the gearbox. Any compromise in the integrity of the housing, such as cracks, leaks, or deformations, can lead to contamination, misalignment, and increased stress on the gears, bearings, and shafts within the gearbox. This can result in accelerated wear, overheating, vibration, and ultimately, catastrophic failure of the gearbox. Therefore, assessing the integrity of the gearbox housing is essential in identifying potential failure modes and implementing preventive maintenance measures to ensure the reliable operation of the gearbox. Additionally, conducting regular inspections and testing of the housing material, structure, and connections can help in detecting any early signs of degradation or damage that could impact the overall performance and longevity of the gearbox.