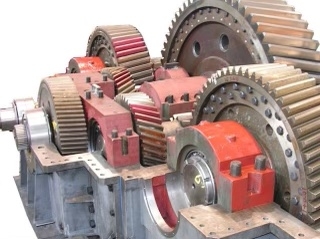

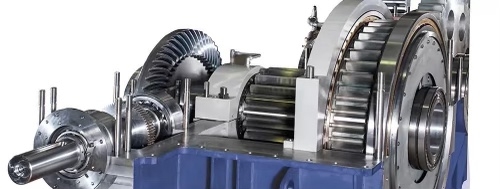

Gearbox Failure Mode Effects Analysis (FMEA)

What are the common failure modes associated with gearbox components such as gears, bearings, and seals?

Gearbox components such as gears, bearings, and seals can experience common failure modes due to factors like pitting, spalling, and wear. Pitting occurs when surface fatigue leads to small craters on the gear teeth, while spalling involves the breaking off of small pieces of material from the gear surface. Wear, on the other hand, occurs gradually over time as the components rub against each other, leading to a decrease in performance and eventual failure of the gearbox.