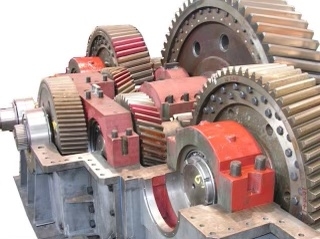

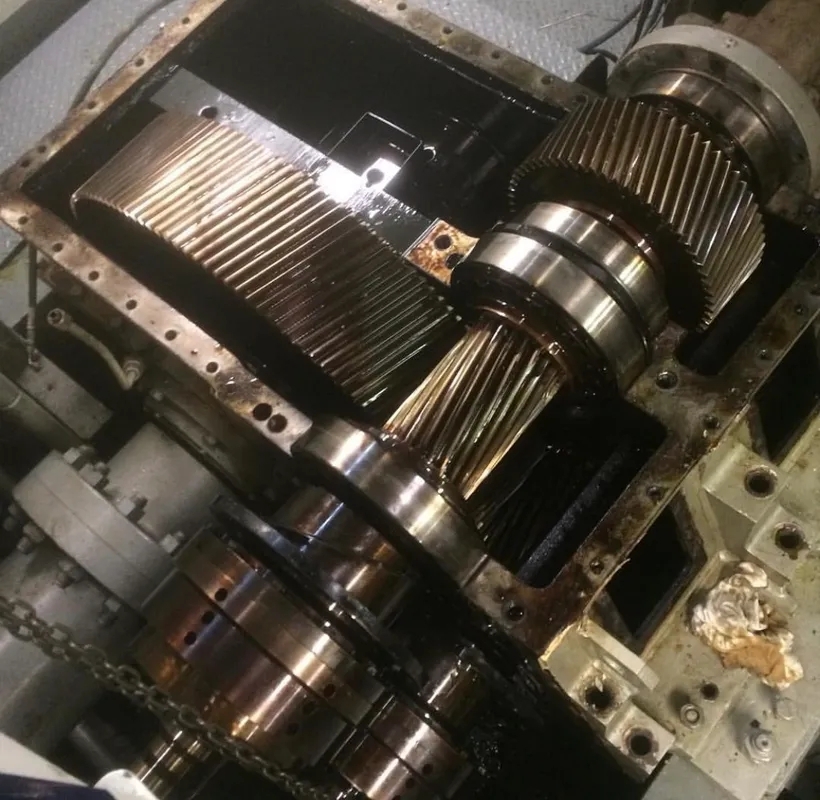

Oil Contamination in Gearboxes

How does oil contamination affect the performance of gearboxes?

Oil contamination can significantly impact the performance of gearboxes by causing increased friction, wear, and overheating of the components. Contaminants such as dirt, metal particles, water, and other foreign substances can lead to accelerated degradation of the gear oil, reduced lubrication efficiency, and ultimately result in premature failure of the gearbox.