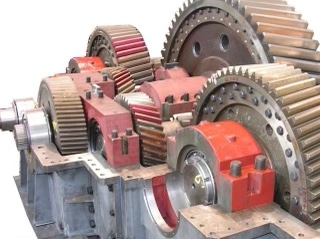

Gearbox Thermal Stress Analysis

How does thermal stress affect the performance of gears in a gearbox?

Thermal stress can significantly impact the performance of gears in a gearbox by causing dimensional changes, material fatigue, and ultimately leading to premature failure. When gears are subjected to high temperatures, they can experience thermal expansion, which can affect their meshing capabilities and overall efficiency. Additionally, thermal stress can lead to changes in material properties, such as hardness and strength, further compromising the gear's performance and durability.