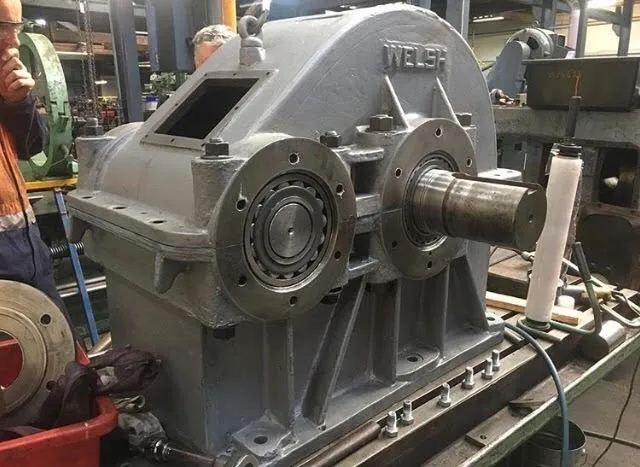

Gearbox Lubricant Degradation

How does oxidation impact the degradation of gearbox lubricants?

Oxidation in gearbox lubricants can have a significant impact on their degradation. When lubricants oxidize, they form harmful byproducts that can lead to increased viscosity, decreased lubricity, and overall reduced performance of the lubricant. This oxidation process can accelerate the breakdown of the lubricant, leading to potential damage to the gearbox components and decreased efficiency of the system.