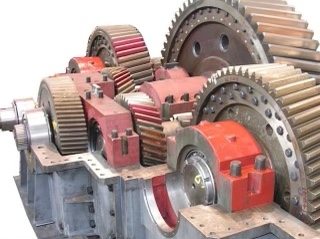

Gearbox Operational Stress Analysis

How does operational stress affect the performance of gears in a gearbox?

Operational stress can significantly impact the performance of gears in a gearbox by causing increased friction, wear, and fatigue. The excessive load and pressure on the gears can lead to accelerated deterioration of the gear teeth, resulting in decreased efficiency and potential failure of the gearbox system. The stress can also cause misalignment of the gears, leading to further issues such as noise and vibration during operation.