Gearbox Stress Testing Methods

How does the gear tooth profile affect the stress distribution in a gearbox during testing?

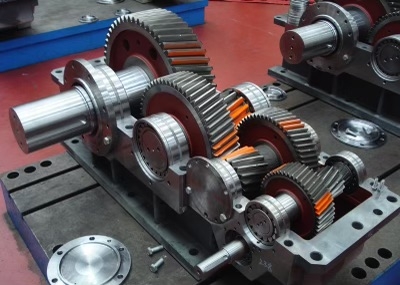

The gear tooth profile plays a crucial role in determining the stress distribution within a gearbox during testing. The shape and size of the gear teeth directly impact how the load is distributed across the gears, affecting the stress levels experienced by each component. A well-designed tooth profile can help evenly distribute the load, reducing the concentration of stress on specific areas and improving the overall durability of the gearbox.