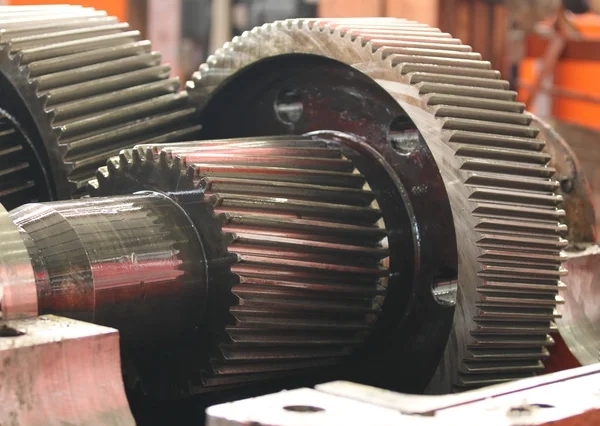

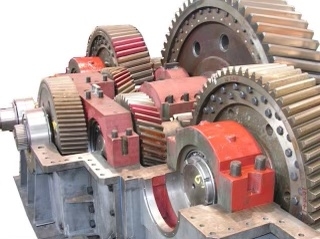

Gearbox Wear Patterns

What are the common wear patterns seen in gearbox teeth?

Common wear patterns seen in gearbox teeth include pitting, scoring, and spalling. Pitting is characterized by small craters or pits on the surface of the teeth, often caused by repeated contact stress. Scoring refers to the presence of scratches or grooves on the teeth, typically caused by abrasive particles or insufficient lubrication. Spalling involves the chipping or flaking of the tooth surface, usually due to material fatigue or overload conditions.