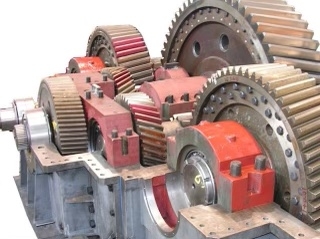

Gearbox End-Of-Life Testing

How does end-of-life testing ensure the reliability and safety of gearboxes?

End-of-life testing plays a crucial role in ensuring the reliability and safety of gearboxes by subjecting them to rigorous testing procedures that simulate real-world operating conditions and stress levels. By testing gearboxes at the end of their expected lifespan, manufacturers can identify any potential weaknesses or defects that may have developed over time, allowing them to make necessary improvements to enhance the overall performance and durability of the gearbox.