Gearbox Fault Diagnosis Algorithms

How can gearbox fault diagnosis algorithms help in predicting potential issues before they occur?

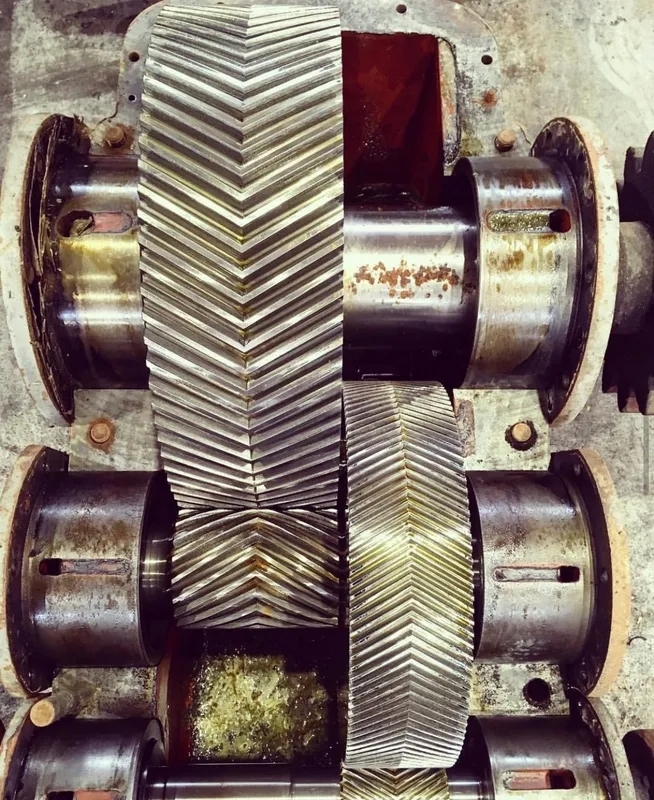

Gearbox fault diagnosis algorithms play a crucial role in predicting potential issues before they occur by analyzing historical data, monitoring key parameters, and detecting patterns that may indicate a future malfunction. By utilizing advanced algorithms and machine learning techniques, these systems can identify early warning signs of gearbox faults, allowing maintenance teams to take proactive measures to prevent costly downtime and repairs.