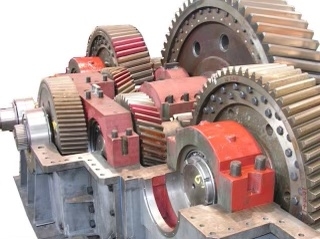

Gearbox Erosion and Corrosion

How does gear oil contamination contribute to gearbox erosion and corrosion?

Gear oil contamination can contribute significantly to gearbox erosion and corrosion. When contaminants such as dirt, water, or metal particles mix with the gear oil, they can create abrasive compounds that wear down the gearbox components over time. This abrasion can lead to increased friction, heat, and ultimately, erosion and corrosion of the gearbox surfaces.

Gearbox Failure Analysis and How It Works