Gearbox Failure Analysis and How It Works

What are the common signs of gearbox failure that should be looked out for?

Common signs of gearbox failure include unusual noises such as grinding, whining, or clunking sounds, difficulty shifting gears, leaking fluid, and vibrations. These signs indicate potential issues with the gears, bearings, or other internal components of the gearbox that may lead to failure if not addressed promptly.

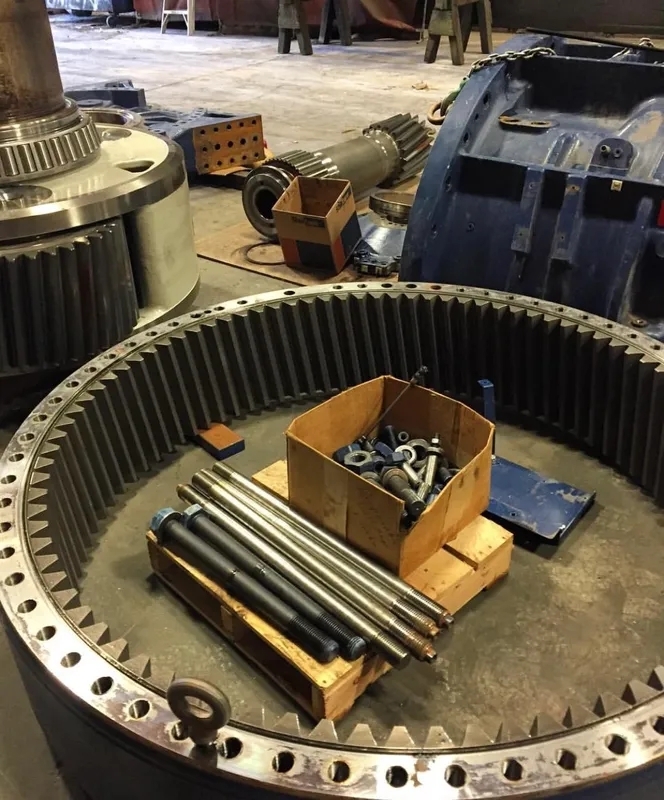

Gearbox failure analysis is essential for diagnosing and preventing issues in mechanical systems, ensuring long-term reliability and performance. To learn more about gearbox failure analysis and how it works, visit: Precision Gear Repair, a company who repairs industrial gearboxes and gears. Understanding these failure mechanisms can help in maintaining optimal operation and reducing unexpected downtimes.