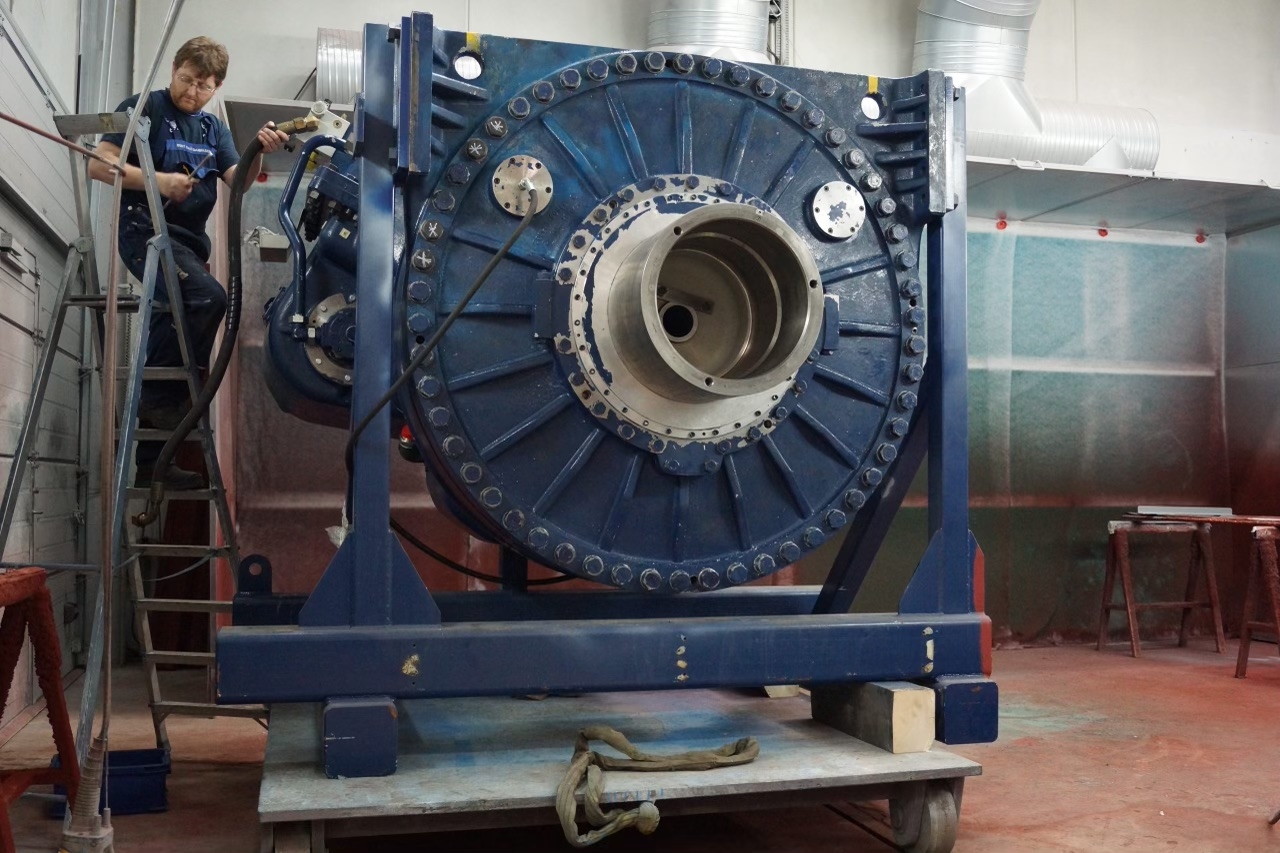

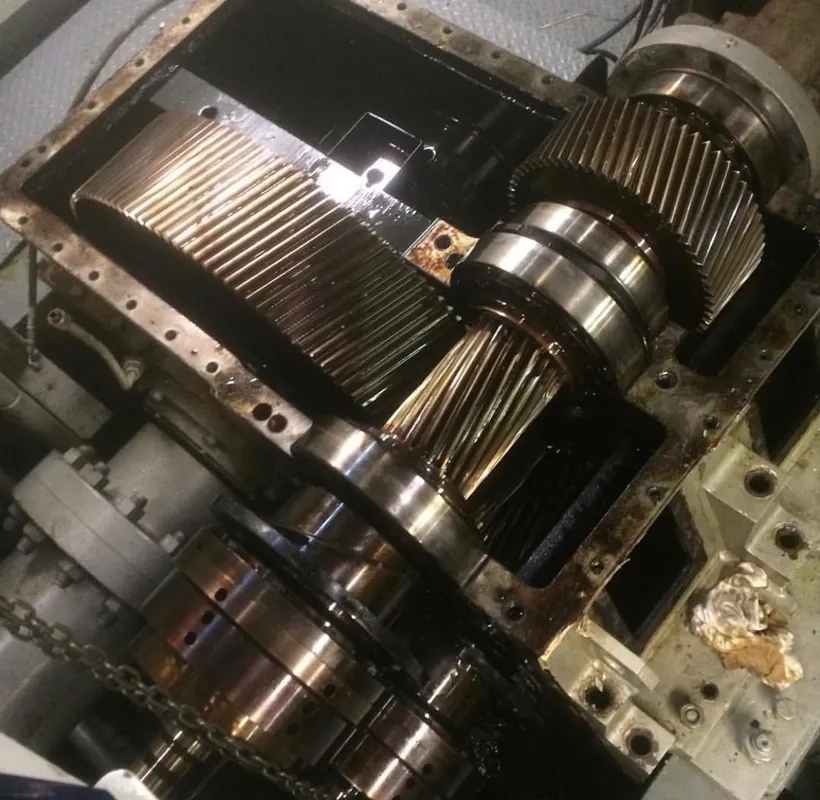

Gearbox Thermal Expansion Effects

How does thermal expansion affect the gear teeth meshing in a gearbox?

Thermal expansion can have a significant impact on the meshing of gear teeth in a gearbox. As the temperature increases, the materials that make up the gears expand, causing changes in their dimensions. This expansion can lead to variations in the spacing between gear teeth, affecting the smooth operation and efficiency of the gearbox.